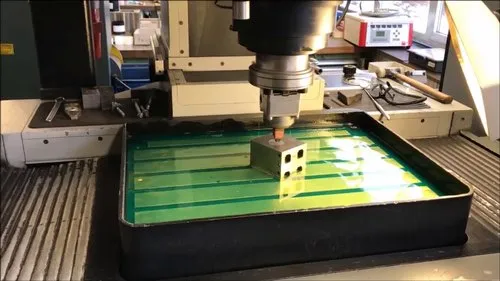

Die sinking EDM, also known as electrical discharge machining, is a technology that is rapidly revolutionizing the manufacturing industry. It is a process of machining metal by utilizing sparks generated from an electrode that is guided over the surface of a metal workpiece.

This method is especially useful for creating intricate shapes and patterns that are difficult to achieve through conventional machining methods.

As the world becomes more focused on precision and efficiency, die sinking EDM is becoming an increasingly popular choice for manufacturers. The benefits of this technology are numerous and range from increased accuracy to reduced production times.

In this article, we will take a closer look at some of the most notable benefits of die sinking EDM and how it is helping to revolutionize the manufacturing industry.

Produces Highly Accurate and Complex Shapes

One of the primary benefits of die sinking EDM is its ability to produce highly accurate and complex shapes with ease. This is because the electrical discharge that is used to cut the metal is guided by a programmable computer, which allows for precise control over the cutting process. This means that manufacturers can produce intricate shapes and patterns that would be impossible to achieve through conventional machining methods.

Produces Parts with Tight Tolerance

Another key benefit of die sinking EDM is its ability to produce parts with very tight tolerances. This is because the electrical discharge is highly precise, which means that manufacturers can produce parts with dimensions that are accurate to within a few thousandths of an inch. This level of precision is especially important for the production of parts for the aerospace, medical, and electronic industries, where tight tolerances are crucial for performance and safety.

Speed and Efficiency

In addition to accuracy and precision, die sinking EDM is also known for its speed and efficiency. Because the electrical discharge can cut through metal quickly and easily, manufacturers can produce parts much faster than they would be able to through conventional machining methods. This can significantly reduce production times and help manufacturers to keep up with growing demand for their products.

Works With a Wide Range of Materials

One of the most unique benefits of edm electrical discharge machining is its ability to work with a wide range of materials, including hard and soft metals, ceramics, and even some types of plastics. This means that manufacturers can produce parts made from a variety of materials, which can be especially useful for the production of complex, multi-material parts.

They are Versatile

Another important benefit of die sinking EDM is its versatility. This technology can be used to produce a wide range of parts, from simple, flat pieces to complex, three-dimensional shapes. This means that manufacturers can produce a wide variety of parts with the same machine, which can help to reduce the number of machines and personnel required for production.

Despite the numerous benefits of die sinking EDM, some manufacturers may still be hesitant to adopt this technology. One of the primary concerns is the cost of the machines, which can be substantial.

However, manufacturers should keep in mind that the cost of the machines will likely be offset by the many benefits they provide, including increased accuracy, reduced production times, and improved product quality.

In conclusion, die sinking EDM is a technology that is rapidly revolutionizing the manufacturing industry. With its ability to produce highly accurate and complex shapes, tight tolerances, and fast production times, it is helping manufacturers to keep up with the growing demand for their products.

So, whether you’re looking to produce parts for the aerospace, medical, or electronic industries, or simply looking to improve the efficiency and quality of your manufacturing process, die sinking EDM is definitely worth considering.

So, don’t be like a fish out of water when it comes to adopting the latest technology in manufacturing. Take the leap and join the revolution with die sinking EDM!